Petrochemical plants contain volatile substances. A single spark can trigger catastrophic events in these environments. Reliable and safe communication is paramount. The Explosion Proof Telephone is an indispensable safety device. These specialized telephones operate without becoming an ignition source. They ensure continuous communication even in hazardous zones.

Key Takeaways

- Explosion Proof Telephones prevent fires and explosions in dangerous plant areas. They stop sparks and control heat, keeping everyone safe.

- These special phones help people talk during emergencies. They make sure important messages get through quickly, even when things are bad.

- Using Explosion Proof Telephones helps plants follow safety rules. This protects workers and keeps the plant running without costly shutdowns.

1. Preventing Ignition in Flammable Atmospheres with an Explosion Proof Telephone

Containing Electrical Sparks and Arcs

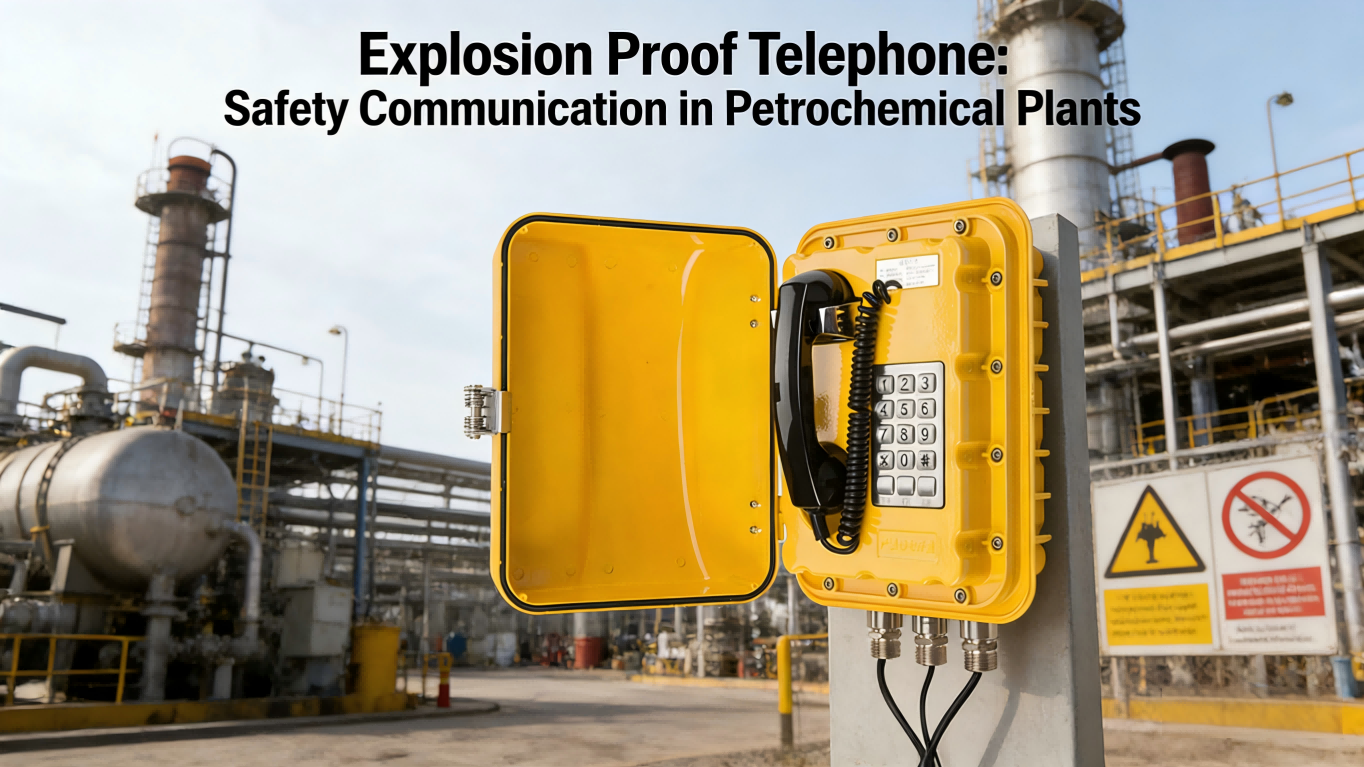

Standard electrical equipment inherently produces sparks and arcs. These electrical discharges commonly occur during routine operation, such as when a switch is flipped, or during a malfunction, like a short circuit. Petrochemical plants contain highly flammable gases, vapors, and dust. In such environments, even a tiny spark possesses enough energy to ignite these volatile substances. This ignition can trigger catastrophic explosions. An Explosion Proof Telephone directly addresses this critical risk. It features a robust, hermetically sealed enclosure. This specialized casing is engineered to contain any internal sparks or arcs completely. It prevents them from escaping into the external, hazardous atmosphere. This design effectively eliminates a primary ignition source, ensuring the communication device itself does not become a catalyst for disaster.

Managing Internal Heat Generation

Electronic components generate heat as they operate. This internal heat can significantly raise the device’s surface temperature. In hazardous petrochemical environments, elevated surface temperatures present a serious ignition risk. They can easily heat flammable gases, vapors, or dust to their auto-ignition point. An Explosion Proof Telephone actively manages this potential hazard. Its design incorporates specialized, thermally conductive materials and advanced heat dissipation techniques. These methods ensure the telephone’s external surface temperature consistently remains below the auto-ignition temperature of any surrounding hazardous materials. This meticulous thermal management prevents heat-related ignitions. It maintains a safe operating environment even in the most volatile conditions. The telephone’s construction actively prevents it from becoming a thermal ignition source, safeguarding personnel and assets.

2. Ensuring Uninterrupted Communication During Emergencies

Facilitating Rapid Emergency Response Coordination

Emergencies in petrochemical plants demand immediate and effective communication. A swift response can prevent minor incidents from escalating into major disasters. Standard communication devices often fail in hazardous environments. They can become damaged by extreme conditions or even act as an ignition source. An Explosion Proof Telephone provides a reliable lifeline. It allows emergency teams to coordinate their actions without delay. Plant operators can quickly relay critical information. This includes the nature of the emergency, its location, and necessary safety protocols. This rapid coordination minimizes response times. It also enhances the overall effectiveness of emergency operations.

Enabling Critical Information Exchange in Crisis

During a crisis, accurate and timely information saves lives. Personnel need to communicate vital details. This includes evacuation routes, hazard levels, and equipment status. Traditional phones might fail due to power outages or environmental damage. An Explosion Proof Telephone is built to withstand these challenges. It ensures continuous communication channels remain open. This allows for the constant exchange of critical information. For example, a supervisor can direct workers away from a gas leak. A maintenance team can receive instructions to shut down a specific valve. This uninterrupted flow of information is crucial. It supports informed decision-making and protects everyone on site.

3. Meeting Stringent Safety Regulations and Compliance Standards

Adhering to ATEX and IECEx Certifications

Petrochemical plants operate under strict international safety regulations. These regulations mandate specialized equipment for hazardous areas. ATEX and IECEx are critical certifications. They ensure equipment is safe for use in potentially explosive atmospheres. Manufacturers design an Explosion Proof Telephone to comply with these rigorous standards. These certifications confirm the telephone will not ignite flammable gases, vapors, or dust. Compliance involves extensive testing. It verifies the device’s ability to contain sparks and manage heat. Adhering to ATEX and IECEx is not optional. It is a legal requirement for operating safely in these high-risk environments. Plants demonstrate their commitment to safety by using certified equipment.

Complying with National Electrical Code (NEC) Requirements

The National Electrical Code (NEC) provides specific guidelines for electrical installations in hazardous locations within the United States. The NEC classifies these areas based on the type of flammable material present and the likelihood of its presence. For example, Class I locations contain flammable gases or vapors. Class II locations contain combustible dusts. Equipment used in these zones must meet specific NEC requirements. This includes design, construction, and installation. An Explosion Proof Telephone is engineered to satisfy these stringent NEC standards. It ensures the communication system integrates safely into the plant’s electrical infrastructure. Compliance with NEC prevents electrical hazards. It also avoids potential fines and operational shutdowns. This adherence is fundamental for maintaining a safe and legally compliant facility.

4. Protecting Personnel from Electrical Hazards

Implementing Intrinsic Safety Design Principles

Petrochemical environments pose significant electrical risks. Intrinsic safety is a crucial design philosophy. It prevents electrical equipment from generating sparks or heat. This design limits the electrical and thermal energy within a system. It ensures that even under fault conditions, the energy remains too low to ignite flammable gases or dust. An Explosion Proof Telephone incorporates these principles. Its circuits operate at very low power. This inherent safety feature protects personnel directly. It eliminates the risk of electrical components becoming an ignition source. This design prevents accidental explosions caused by electrical faults.

Providing Robust Electrical Isolation and Grounding

Proper electrical isolation and grounding are fundamental safety measures. They protect personnel from electric shock. Electrical isolation separates circuits or equipment from power sources. This prevents unintended current paths. Robust grounding provides a safe path for fault currents. It directs excess electricity away from equipment and personnel. This prevents dangerous voltage buildup. In petrochemical plants, these measures are critical. They safeguard workers who operate near electrical equipment. They also ensure the integrity of the communication system. This dual protection minimizes electrical hazards. It creates a safer working environment for all plant employees.

5. Guaranteeing Durability in Harsh Industrial Environments

Resisting Corrosive Chemicals and Abrasive Substances

Petrochemical plants present a highly aggressive environment for equipment. Corrosive chemicals, including various acids, alkalis, and solvents, are frequently present in the air or as splashes. Abrasive substances, such as fine particulate matter or grit, also circulate. Standard communication devices cannot withstand these conditions. Their plastic casings become brittle. Metal parts corrode rapidly. This leads to premature failure and potential safety hazards. Specialized telephones, however, feature superior construction. Manufacturers build them from marine-grade stainless steel or advanced, chemical-resistant polymers. These materials resist degradation from chemical exposure. They also endure constant abrasion. This robust material selection ensures the telephone’s long-term functionality. It maintains its structural integrity and protective properties. This resistance is vital for reliable communication in such challenging settings.

Withstanding Extreme Temperatures, Dust, and Moisture

Petrochemical facilities operate across diverse and often extreme climatic conditions. Equipment must function reliably in scorching heat, sometimes exceeding 50°C (122°F). It also needs to perform in freezing temperatures, well below 0°C (32°F). Fine dust particles are common in many operational areas. High humidity, heavy rain, and even direct water spray from cleaning processes are also prevalent. Conventional telephones fail under these environmental stresses. Their electronics overheat or freeze. Dust clogs moving parts. Moisture causes short circuits. An Explosion Proof Telephone is specifically engineered for resilience. Its sealed enclosures protect all internal electronics from dust ingress and moisture. These devices typically boast high Ingress Protection (IP) ratings, like IP66 or IP67. They also incorporate components designed for wide operational temperature ranges. This comprehensive protection ensures consistent, reliable communication. It functions effectively regardless of the environmental severity. This inherent durability is critical for maintaining operational continuity and safety in demanding industrial settings.

6. Facilitating Efficient Evacuation Procedures

Delivering Clear and Immediate Evacuation Directives

Effective evacuation relies on clear, immediate instructions. In a petrochemical plant, a delay or misunderstanding can have severe consequences. Standard communication systems often fail under duress or in hazardous conditions. They might suffer damage from explosions, fires, or corrosive substances. Specialized telephones, however, ensure directives reach personnel without interruption. Plant management can broadcast critical information instantly. This includes the nature of the threat, the location of the incident, and designated safe assembly points. Clear communication minimizes confusion. It allows workers to react quickly and follow established safety protocols. This direct line of communication is vital for saving lives during an emergency.

Coordinating Safe Personnel Movement from Danger Zones

Evacuating a large industrial facility requires precise coordination. Personnel must move safely away from immediate danger. They need guidance through complex plant layouts. Communication devices play a crucial role in this process. Supervisors can use these robust telephones to direct teams along safe evacuation routes. They can also receive updates on personnel accountability. For instance, a control room can instruct workers to avoid a specific area due to a chemical spill. Field personnel can report their status and location. This continuous information exchange helps manage the flow of people. It prevents secondary incidents and ensures everyone reaches safety efficiently. Reliable communication during evacuation is non-negotiable for personnel safety.

7. Supporting Critical Maintenance and Operational Coordination

Enabling Safe Routine Communication in Hazardous Areas

Petrochemical plants require constant maintenance and operational oversight. Technicians perform routine inspections, repairs, and adjustments in areas containing flammable materials. Standard communication devices pose a significant ignition risk in these zones. They can generate sparks or excessive heat. An Explosion Proof Telephone provides a secure communication channel for these daily tasks. Workers can report findings, request assistance, or receive instructions without compromising safety. This reliable communication ensures personnel complete their duties efficiently. It also prevents potential hazards from escalating. Safe, routine communication is fundamental for maintaining plant integrity and preventing accidents during normal operations.

Enhancing Team Collaboration for Operational Adjustments

Effective collaboration among teams is crucial for smooth plant operations. Operational conditions often change, requiring quick adjustments. For example, a team might need to reroute a pipeline or modify a process setting. These changes demand immediate and clear communication between control rooms, field operators, and maintenance crews. Reliable communication systems facilitate this coordination. Teams can discuss issues in real-time. They can make informed decisions quickly. This enhanced collaboration minimizes downtime and optimizes production. It also ensures all personnel understand their roles during operational shifts. This seamless information exchange improves overall plant efficiency and safety.

8. Minimizing the Risk of Catastrophic Accidents

Eliminating Potential Ignition Sources from Communication Devices

Petrochemical plants inherently contain flammable gases, vapors, and combustible dusts. Standard communication devices, such as regular mobile phones or two-way radios, pose a significant ignition risk in these environments. These devices can generate electrical sparks during routine operation, such as when a button is pressed, or due to internal faults like a short circuit. They also produce heat, which can exceed the auto-ignition temperature of surrounding hazardous materials. Eliminating these potential ignition sources is paramount for maintaining safety. Specialized communication equipment, like an Explosion Proof Telephone, is specifically engineered to prevent such occurrences. Its robust design contains all potential sparks within its enclosure and manages internal heat effectively. This ensures the device itself does not become the catalyst for an explosion, thereby removing a critical hazard from the operational environment.

Preventing Minor Incidents from Escalating into Disasters

Minor operational anomalies or equipment malfunctions can quickly escalate into catastrophic events within a petrochemical facility. A small leak, an unusual pressure reading, or a localized fire requires immediate and precise attention. Effective communication plays a vital role in preventing such escalation. Personnel must report these incidents promptly and accurately. Control room operators need to issue rapid, clear instructions to field teams. Reliable communication channels allow for quick assessment of the situation and a coordinated response from all relevant departments. This enables teams to implement containment procedures, initiate emergency shutdowns, or deploy resources before a minor issue transforms into a major disaster. Timely and uninterrupted information exchange minimizes the window for an incident to grow, thereby protecting both human life and valuable plant assets.

9. Reducing Financial Losses and Operational Downtime

Avoiding Costly Plant Damage and Infrastructure Loss

Explosions in petrochemical plants cause immense physical destruction. They damage critical infrastructure. This includes complex pipeline networks, sensitive reactor vessels, and sophisticated control systems. Repairing or replacing these specialized components costs millions of dollars. It also demands extensive time and resources. An Explosion Proof Telephone prevents ignition. It directly reduces the risk of such catastrophic events. This protection saves companies from massive financial burdens associated with rebuilding. It also preserves valuable assets. Investing in these specialized telephones represents a proactive financial decision. It safeguards the plant’s physical integrity and long-term operational viability.

Ensuring Business Continuity and Production Stability

Plant shutdowns following an incident lead to substantial production losses. Every hour of downtime costs companies significant revenue. It also impacts market supply chains and customer commitments. Reliable communication prevents minor operational issues from escalating into major incidents. It ensures quick resolution of problems. This minimizes operational interruptions. Explosion Proof Telephones guarantee continuous communication. They allow teams to coordinate effectively during both normal operations and critical emergencies. This capability helps maintain production schedules. It ensures business continuity even when facing challenges. Companies protect their bottom line by preventing costly shutdowns. They also maintain their market position and reputation.

10. Enhancing Overall Plant Safety Culture and Worker Confidence

Demonstrating a Proactive Commitment to Employee Safety

Companies show their dedication to employee well-being by investing in specialized safety equipment. Providing Explosion Proof Telephones goes beyond mere compliance. It signals a strong commitment to protecting every worker. This visible investment builds trust among the workforce. Employees feel valued and protected when management prioritizes their safety. This proactive approach fosters a positive safety culture. It encourages workers to adopt safe practices themselves. A safe environment also reduces anxiety. This allows employees to focus better on their tasks. Ultimately, a strong safety commitment improves morale and productivity.

Fostering a Culture of Vigilance and Risk Mitigation

Reliable communication tools empower employees. They encourage workers to report potential hazards without delay. An Explosion Proof Telephone ensures they can always communicate from any hazardous zone. This capability promotes constant vigilance. Workers become more aware of their surroundings. They actively identify and report risks. This immediate feedback loop helps mitigate dangers quickly. It prevents minor issues from becoming major incidents. The presence of such robust safety equipment reinforces the importance of risk mitigation. It encourages everyone to take an active role in maintaining a safe workplace. This collective effort strengthens the plant’s overall safety culture. It creates a more secure environment for all personnel.

Petrochemical plants are inherently dangerous environments due to flammable gases, vapors, and dust. An Explosion Proof Telephone is not merely a technological upgrade; it is a fundamental safety imperative.

Their ability to provide reliable communication without posing an ignition risk directly safeguards lives, protects assets, and ensures regulatory compliance.

Investing in these specialized communication systems is a non-negotiable aspect of responsible plant operation and a cornerstone of a robust safety strategy.

FAQ

What makes a telephone “explosion-proof”?

Manufacturers design these phones to contain sparks and manage heat. This prevents ignition of flammable gases or dust. They use robust, sealed enclosures and specialized materials.

Are these phones only for emergencies?

No, they serve daily operational needs too. They enable safe routine communication in hazardous areas. This supports maintenance and operational coordination.

How do these phones meet safety standards?

They comply with strict certifications like ATEX and IECEx. They also meet National Electrical Code (NEC) requirements. These standards ensure safe operation in explosive atmospheres.