Our Explosion-Proof Telephone models are built for survival in the toughest environments. They use specialized materials and strong sealed designs. Advanced internal components make them very resilient. These Explosion-Proof Telephones work reliably where standard communication devices fail. They ensure safety and continuous operation in hazardous industrial settings.

Key Takeaways

- Our special telephones use strong materials like aluminum and stainless steel. These materials help the phones work in very hot or very cold places.

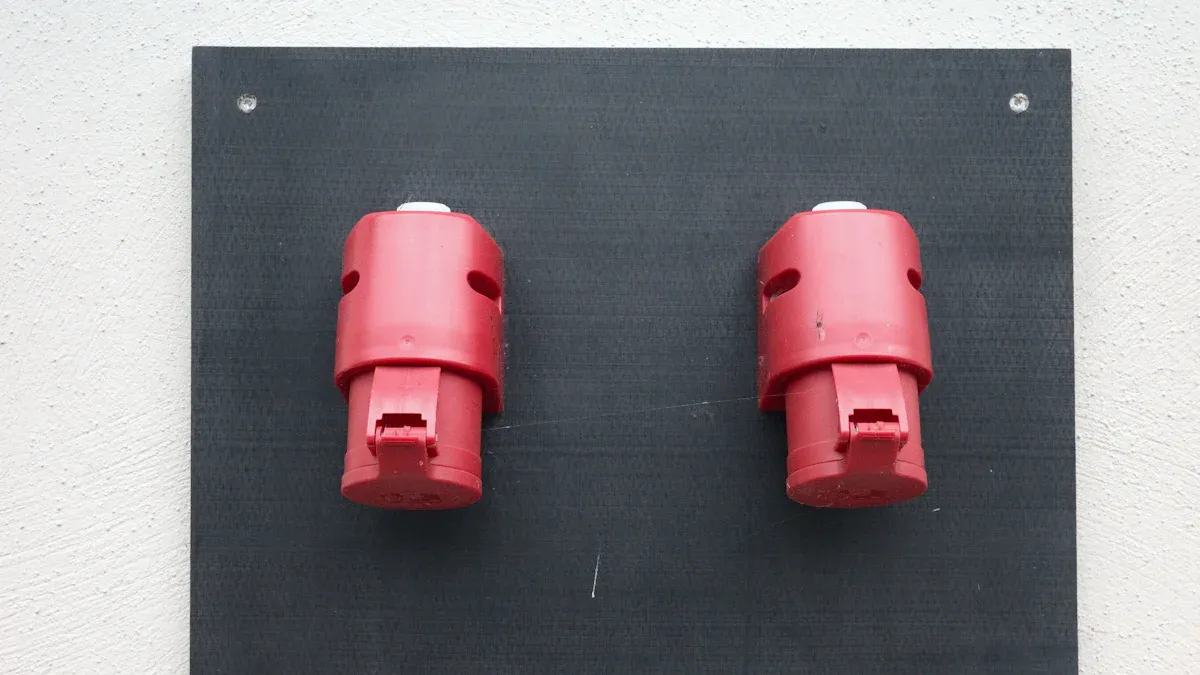

- The telephones have a sealed design. This stops bad gases or liquids from getting inside. It also keeps sparks from coming out.

- The phones have tough electronic parts inside. We test them a lot. This makes sure they work well in dangerous places.

Material Science: The Foundation of Our Explosion-Proof Telephone’s Resilience

High-Performance Enclosure Materials for Temperature Extremes

Our Explosion-Proof Telephone models begin their journey to extreme resilience with carefully chosen enclosure materials. We select these materials for their ability to perform under intense heat and severe cold. For instance, specialized aluminum alloys form the primary housing. These alloys offer excellent strength and effectively dissipate heat, preventing internal components from overheating in hot environments. They also maintain their structural integrity when temperatures drop far below freezing.

Tip: Aluminum alloys are lightweight yet incredibly strong, making them ideal for protective enclosures that need to withstand physical stress and temperature fluctuations.

Another key material is high-grade stainless steel. Manufacturers use stainless steel in areas requiring even greater resistance to thermal shock and physical impact. This material does not warp or become brittle across a vast temperature range. It provides a robust shield, ensuring the telephone’s internal workings remain safe and operational, no matter how extreme the external conditions become.

Corrosion-Resistant Coatings and Components for Our Explosion-Proof Telephone

Beyond temperature, corrosive gases pose a significant threat in many industrial settings. Our Explosion-Proof Telephone combats this with advanced corrosion-resistant coatings and components. We apply multi-layer protective coatings to all external surfaces. These coatings, often epoxy or specialized powder coats, create an impenetrable barrier. They prevent acids, alkalis, salt spray, and other aggressive chemicals from reaching and damaging the underlying metal.

Inside the telephone, engineers select components specifically for their inherent resistance to corrosion. For example, they use stainless steel hardware, such as screws and mounting brackets. Circuit boards receive a conformal coating. This thin, polymeric film covers the electronic components, protecting them from moisture, dust, and corrosive vapors. This comprehensive approach ensures that both the exterior and interior of the telephone remain unaffected by harsh chemical atmospheres, guaranteeing long-term reliability and safety.

Design Principles for Uncompromised Durability of Our Explosion-Proof Telephone

Hermetically Sealed Enclosures and Gasketing

Our design team builds these telephones like a fortress. They use hermetically sealed enclosures. This means the telephone’s casing forms an airtight and watertight barrier. No gas, liquid, or dust can get inside. This seal is crucial for safety in hazardous areas. It prevents sparks from escaping and igniting flammable substances.

Think of it this way: A perfectly sealed jar keeps its contents fresh. Our telephone’s enclosure does the same, but it protects sensitive electronics from a hostile outside world.

Specialized gaskets play a big role in this sealing process. These gaskets are not just ordinary rubber. Manufacturers make them from materials like silicone or EPDM. These materials resist chemicals and extreme temperatures. They stay flexible in the cold and do not degrade in the heat. This ensures the seal remains tight over many years, even in corrosive environments. The precise fit of these gaskets guarantees the telephone’s internal components stay safe and dry.

Thermal Management Systems for Our Explosion-Proof Telephone

Extreme temperatures do not just come from outside. The telephone’s internal electronics also generate heat. Our engineers design effective thermal management systems to handle this. The robust metal casing itself acts as a large heat sink. It draws heat away from the internal components and dissipates it into the surrounding air. This passive cooling method works without moving parts, which increases reliability.

In very hot environments, this design prevents overheating. It keeps the internal temperature within safe operating limits. In cold conditions, the enclosure helps insulate the components. This ensures they start up and function correctly. This careful thermal design means the Explosion-Proof Telephone performs reliably, whether it is in a scorching desert or a freezing arctic facility.

Impact and Vibration Resistance

Industrial settings are often rough places. Equipment can experience bumps, drops, and constant vibrations. Our telephones withstand these physical challenges. We design the housing to absorb shocks. It uses thick walls and reinforced corners. This protects the internal electronics from direct impact forces.

Inside, engineers mount all critical components securely. They use specialized fasteners and sometimes even shock-absorbing materials. This prevents parts from coming loose or breaking during heavy vibration. For example, machinery can cause continuous shaking. Our design ensures the telephone maintains its structural integrity and continues to operate without interruption. This robust construction means the telephone stays functional, even after accidental impacts or prolonged exposure to harsh industrial vibrations.

Advanced Internal Components and Rigorous Testing for Our Explosion-Proof Telephone

Industrial-Grade Electronics for Temperature Stability

Our Explosion-Proof Telephone models rely on specialized industrial-grade electronics. These are not your everyday components. Manufacturers specifically design them to handle wide temperature swings. They perform reliably whether it is extremely hot or bitterly cold. These robust parts resist thermal stress. This ensures the telephone’s internal systems remain stable and functional. They keep communicating clearly, no matter the external climate.

Conformal Coating and Encapsulation of PCBs

Inside each telephone, circuit boards receive critical protection. We apply a conformal coating. This thin, protective layer shields the electronics from moisture, dust, and corrosive vapors. Think of it as an invisible armor for the sensitive components. For even greater resilience, some boards undergo encapsulation. This process fully encloses them in a durable resin. It provides superior defense against physical shock and chemical attack. This meticulous protection extends the telephone’s lifespan in harsh environments.

Adherence to International Standards and Environmental Stress Testing

Our telephones do not just claim durability; they prove it. They adhere to strict international standards, such as ATEX and IECEx. These certifications confirm their safety for hazardous locations. We also subject every design to rigorous environmental stress testing. This includes extreme temperature cycling, high humidity exposure, and intense vibration tests. These trials simulate the toughest real-world conditions. They ensure the Explosion-Proof Telephone performs flawlessly when you need it most. This thorough testing guarantees its unwavering reliability and safety.

Our Explosion-Proof Telephones are carefully engineered. They feature advanced materials, robust designs, and specialized components. We rigorously test and certify all of them. This commitment ensures they reliably withstand extreme temperatures and corrosive gases. They guarantee uninterrupted communication and enhanced safety in the most demanding industrial settings.

FAQ

What makes these telephones explosion-proof?

Our telephones feature robust, sealed enclosures. They prevent sparks from escaping. This stops ignition of flammable gases or dust.

How long do these telephones last in harsh conditions?

They last for many years. High-quality materials and rigorous testing ensure long-term durability. They withstand extreme temperatures and corrosive elements.

Can these telephones work in freezing temperatures?

Yes, they can. Engineers design them with specialized materials. These materials maintain performance in extremely cold environments.